For belt applications which require minimum elongation, maximum flexibility, high resistance to impact and tearing, in the medium and high range of resistance, the use of KAUFLEX belts is recommended, with a FLEXIMATR steel mesh carcass.

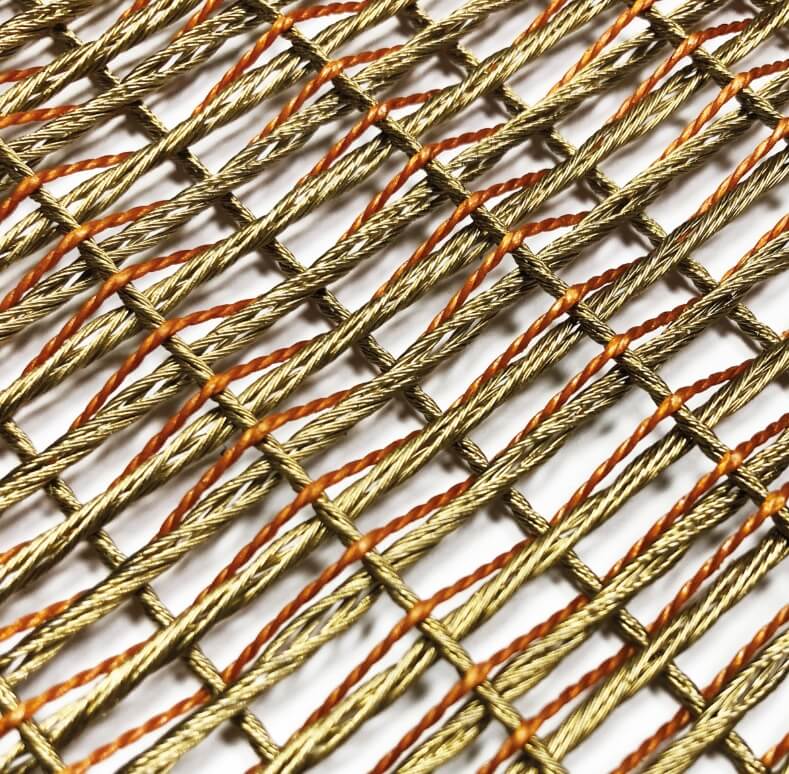

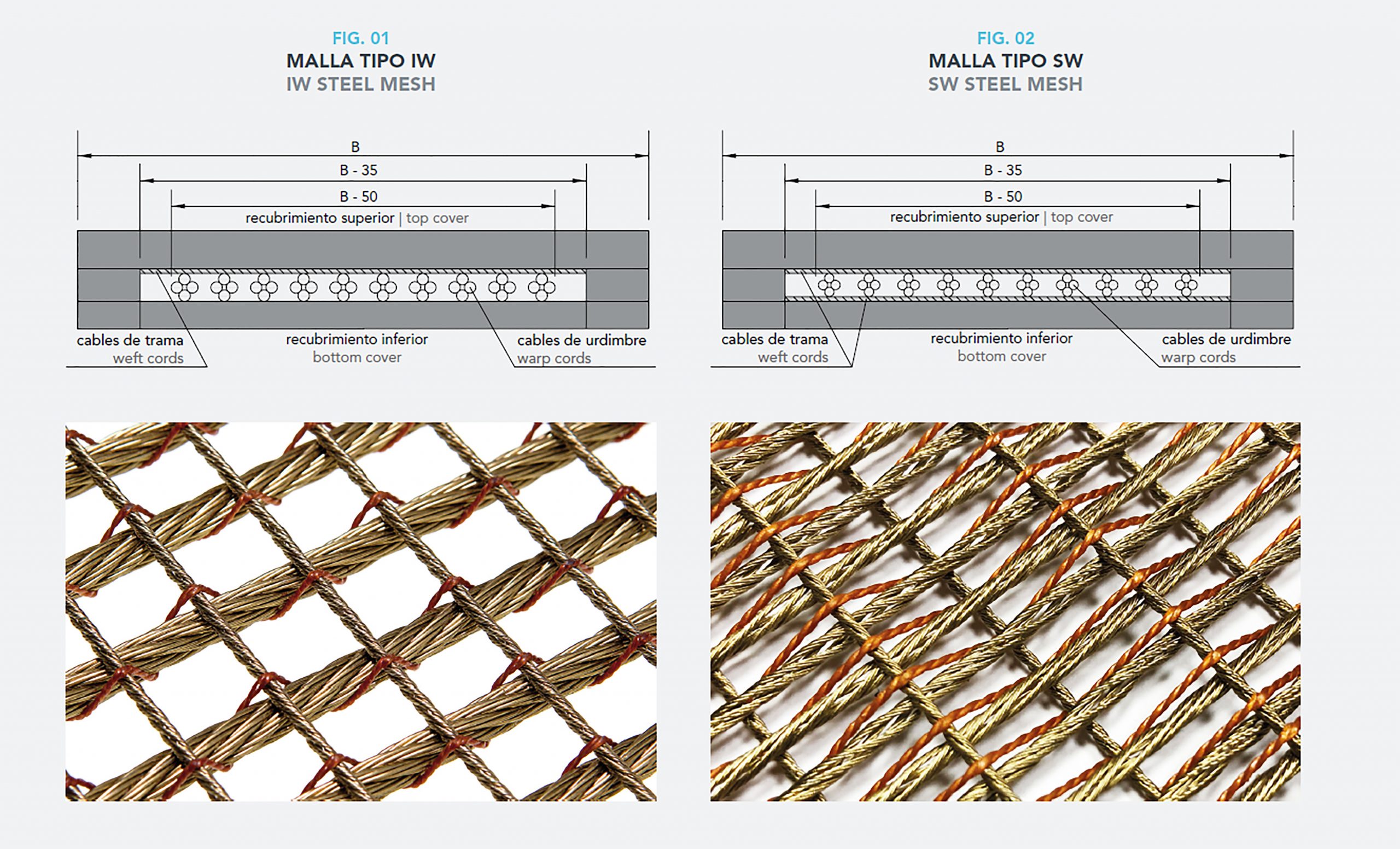

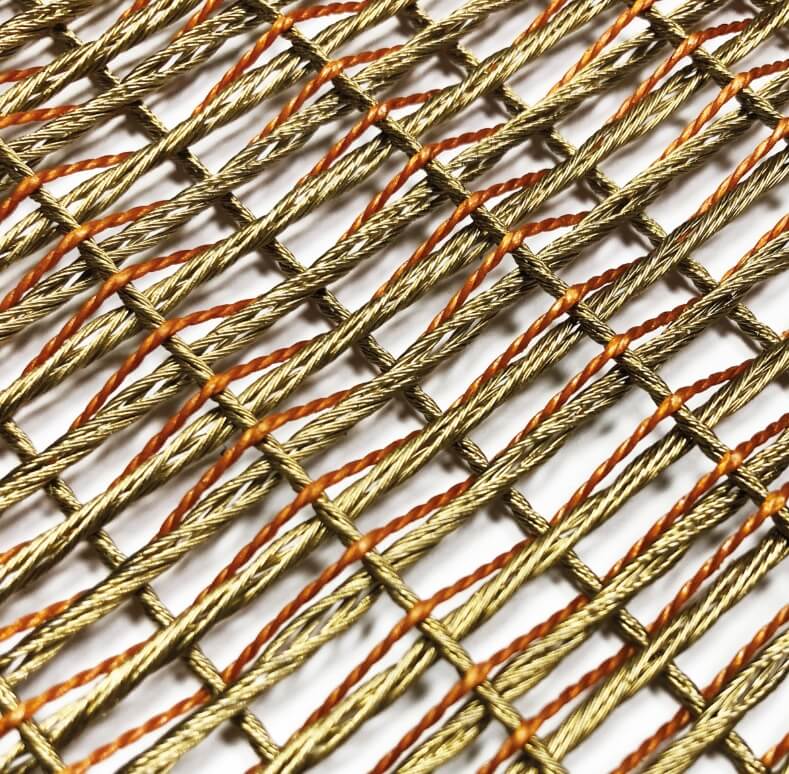

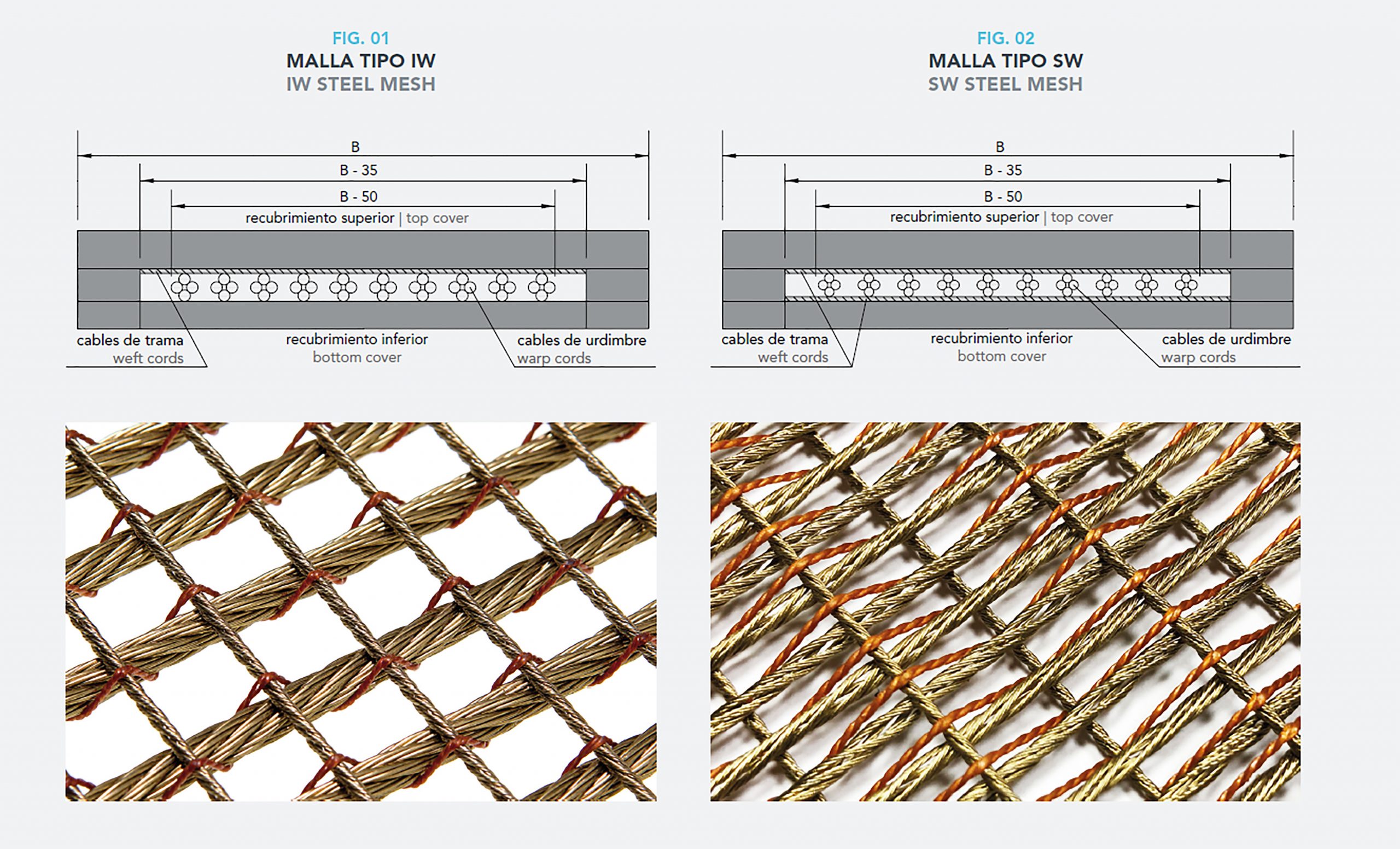

This mesh consists of a steel mesh warp in the longitudinal sense and one or two weft cords, also made of steel, in the transversal sense. The cords are brass-plated for protection.

Within this range of casings, there are standard types with one or two transverse weaves, which can be rigid, where appropriate, which favors applications such as bucket elevators, belts with flat installation resistant to impacts and longitudinal tears (log transport, etc.), and with the additional advantage of being able to be applied in the entire range of resistances and routes of the conventional multi-layer EP textile belt. It presents a significant improvement when it comes to breaking resistance and high transport lengths since, in addition to not having a significant cost difference, it allows the lengths of the tensioners, the diameters of the drums and the energy consumed by the installation to be reduced.

This construction gives us versatility as manufacturers as far as a fast response is concerned, the capacity to manufacture short measurements, etc. and an advantage for users as they have access to highly resistant belts with greater guarantees and flexibility, a lighter weight, less elongation and a greater capacity to absorb impacts etc. than their multi-layer textile equivalents. They are also resistant to longitudinal tearing, which is necessary in numerous fields of application. They are significantly better when it comes to resistance to breakage and to long distances, as there is no significant difference in cost and it reduces the length of take-up, the pulley diameters and the electricity consumed.