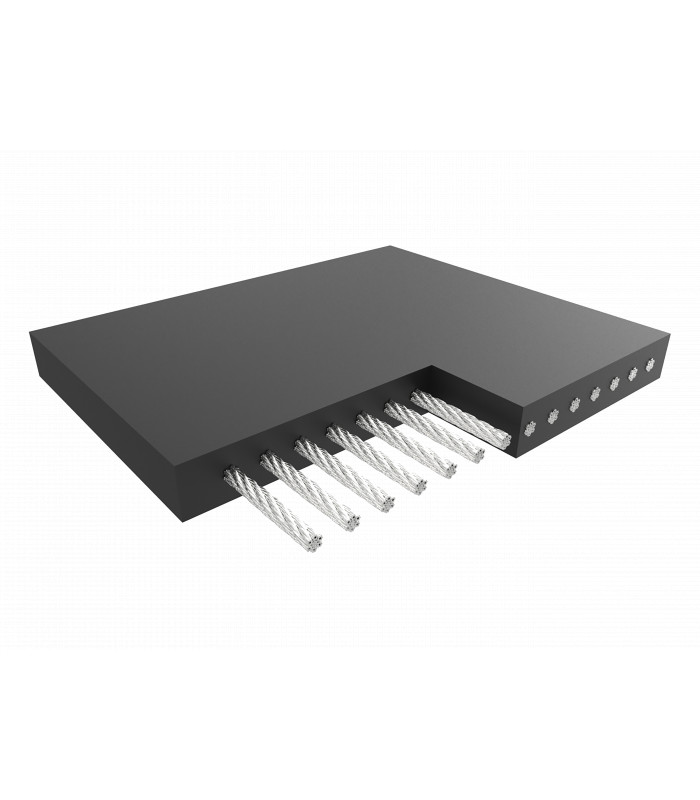

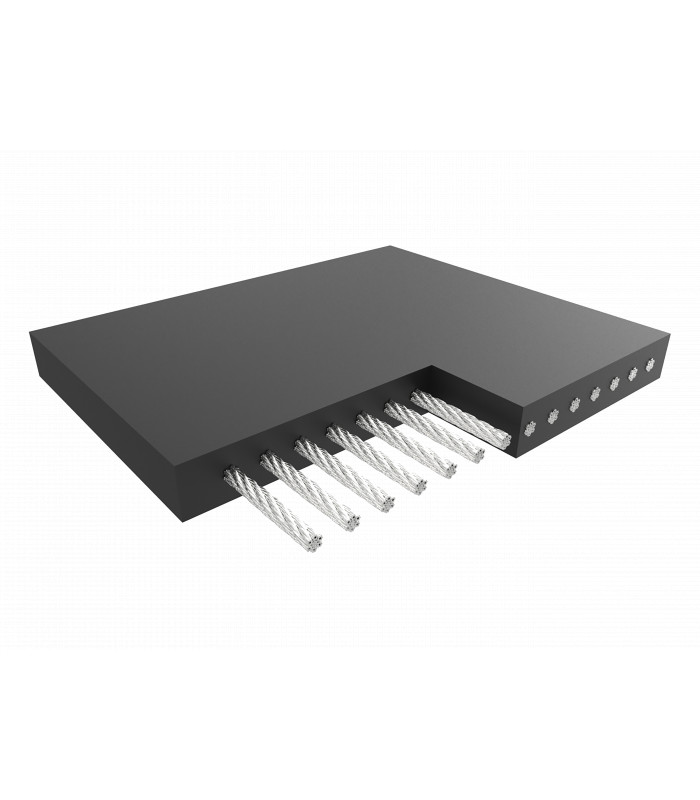

KAUSTEEL belts are the perfect solution for covering long distances, bearing high tension and conveying heavier loads. Given their reduced elongation (close to 0.3%) and high resistance to impact, KAUSTEEL is ideal for an installation measuring several kilometres.

The threads of the warp cords are galvanized and totally saturated in rubber. Cords woven to the left and to the right are alternated in order to guarantee the belt’s straight travel. Transversal rigidity is obtained from the rubber, and as it is more flexible than the fabric used to manufacture. Its great flexibility allows the use of drums with a smaller diameter than textile belts of equal resistance.

When greater resistance to longitudinal tearing is required, a layer of fabric (T) is added as a weft, or steel cords (S) with lower resistance than the longitudinal ones. A layer can be added to either one or both faces of the carcass. Kausteel belts can be made in different rubber qualities, depending on the material to be carried.

The threads of the warp cords are galvanized and totally saturated in rubber. Cords woven to the left and to the right are alternated in order to guarantee the belt’s straight travel. Transversal rigidity is obtained from the rubber, and as it is more flexible than the fabric used to manufacture. When greater resistance to longitudinal tearing is required, a layer of fabric (T) is added as a weft, or steel cords (S) with lower resistance than the longitudinal ones. A layer can be added to either one or both faces of the carcass. Kausteel belts can be made in different rubber qualities, depending on the material to be carried.

Within this range of casings, there are standard types with one or two transverse weaves, which can be rigid, where appropriate, which favors applications such as bucket elevators, belts with flat installation resistant to impacts and longitudinal tears (log transport, etc.), and with the additional advantage of being able to be applied in the entire range of resistances and routes of the conventional multi-layer EP textile belt. It presents a significant improvement when it comes to breaking resistance and high transport lengths since, in addition to not having a significant cost difference, it allows the lengths of the tensioners, the diameters of the drums and the energy consumed by the installation to be reduced.

EP belts, it provides greater troughability. Its great flexibility enables the use of pulleys with a smaller diameter than on textile belts with the same tensile strength.