Resources

Key steps to prevent your bucket elevator from breaking

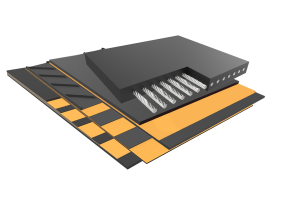

Sometimes an incorrectly installed splice or an oversized conveyor belt can damage the elevator to the point of complete failure. That is why at Kauman it is recommended not to settle for the durability or design of the belt supplied with elevator equipment years ago, since both the materials and the belt design have evolved.

Kauman provides a short training pill summarizing the key points to review and demand from your bucket elevator belt supplier:

- Recalculate and design the elevator belt using dedicated software.

- Redefine the design and type of internal steel mesh reinforcement.

- If there is no cable-free zone, make sure to calculate the loss of steel cables drilled by the splice and the bucket!

- Introduce improvements in high-temperature EPDM rubber compounds.

- Use upgraded splice designs in line with the strength of your belt.

- Provide splice installation, maintenance, and tightening instructions.

- Be careful with excessive tightening over the years; the rubber deforms and can be pushed out of the splice, creating bumps and cracks.

At Kauman, development progresses alongside customers and distributors through real-life experiences, installations, and internal product improvement projects. For this reason, among other factors, the company has become a European leader in the manufacture of belts for bucket elevators.