There are various different options when using a conveyor belt as a bucket elevator, depending on the facility.

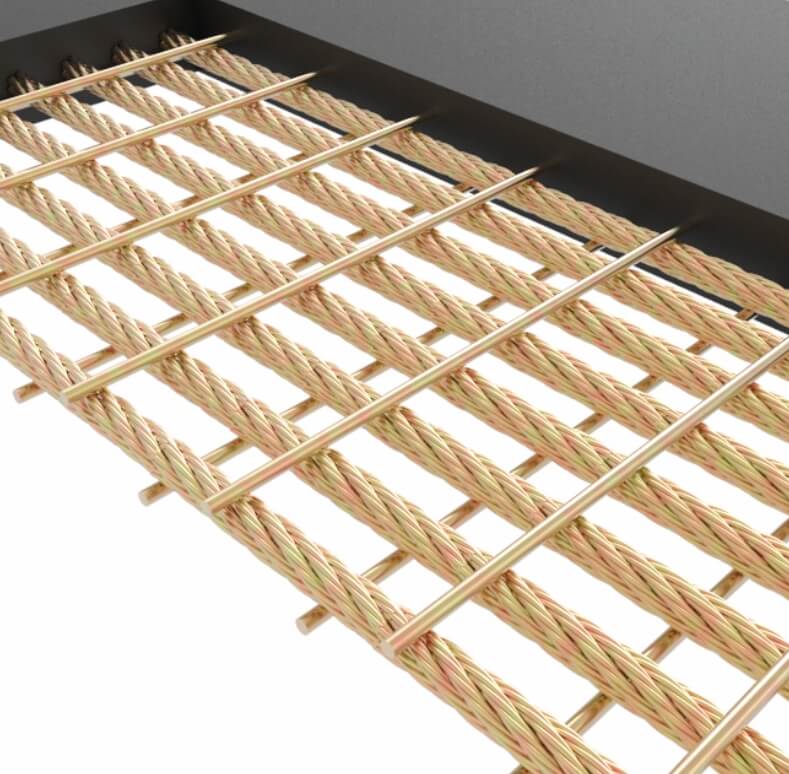

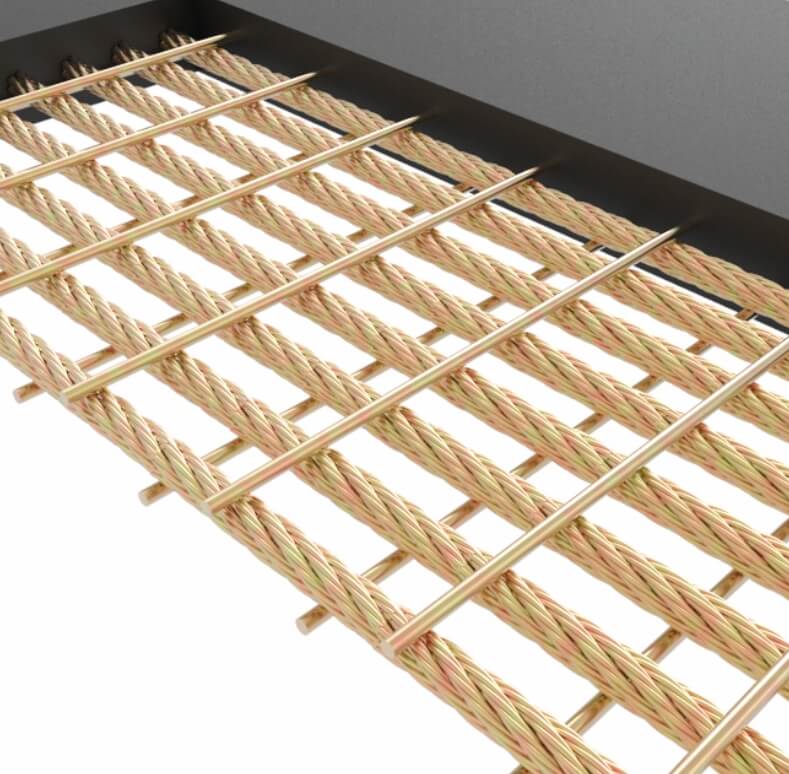

In general, it is important for the belt to be highly resistant to transversal breakage in the carcass in order to bear the force produced in holding the buckets. This resistance in the weft can be improved with specially reinforced fabrics. If transversal rigidity is also required, specially rigid fabrics can be used in the weft.

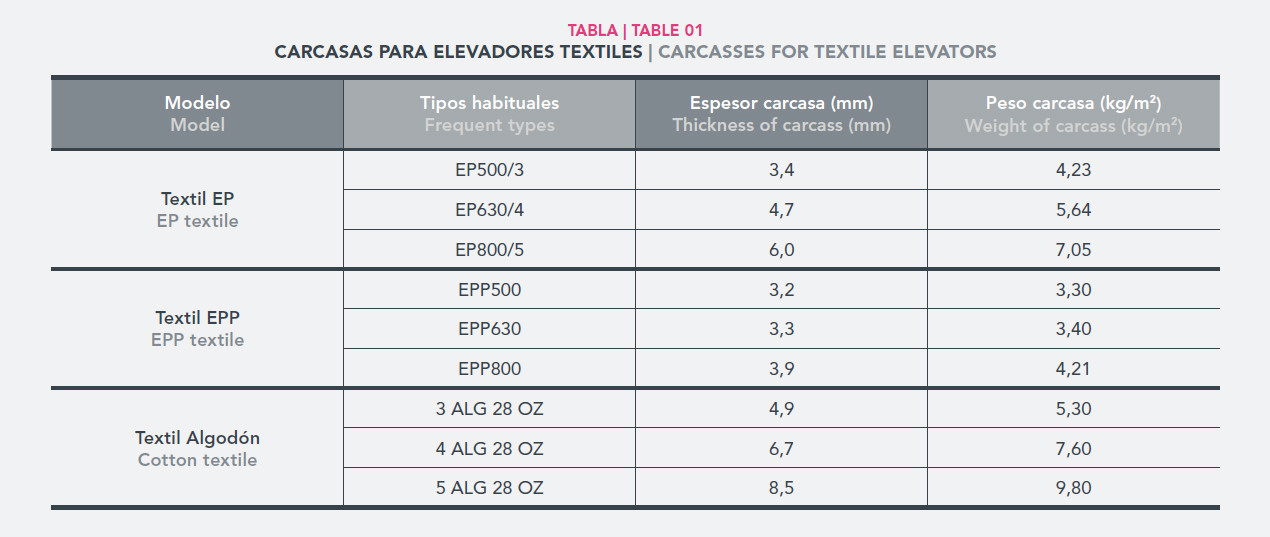

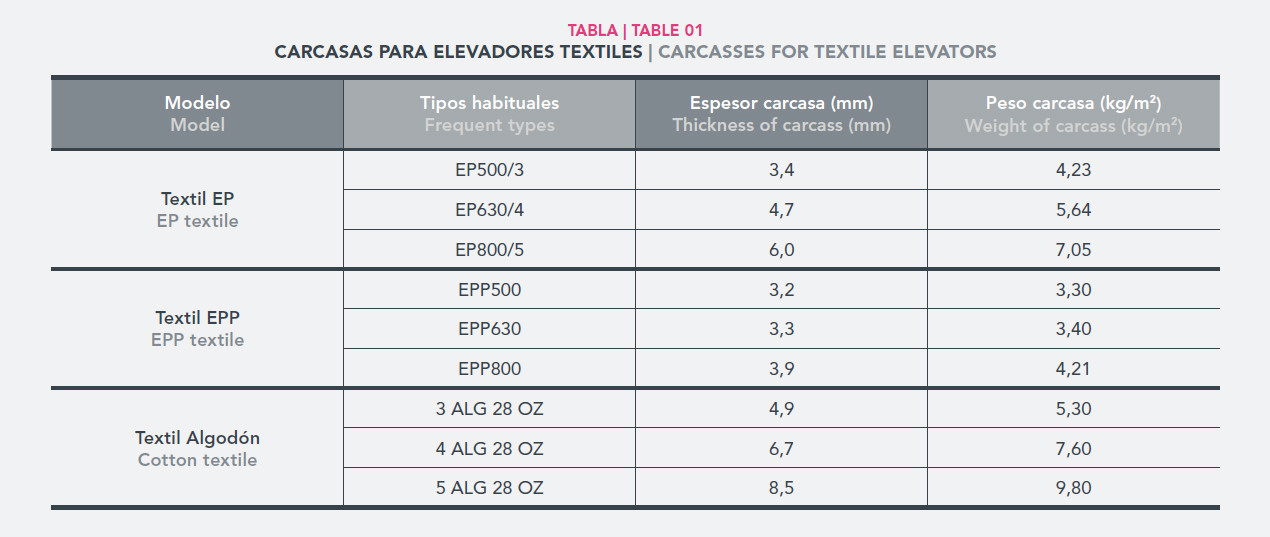

Within this range of casings, there are standard types with one or two transverse weaves, which can be rigid, where appropriate, which favors applications such as bucket elevators, belts with flat installation resistant to impacts and longitudinal tears (log transport, etc.), and with the additional advantage of being able to be applied in the entire range of resistances and routes of the conventional multi-layer EP textile belt. It presents a significant improvement when it comes to breaking resistance and high transport lengths since, in addition to not having a significant cost difference, it allows the lengths of the tensioners, the diameters of the drums and the energy consumed by the installation to be reduced.

This resistance in the weft can be improved with specially reinforced fabrics. If transversal rigidity is also required, specially rigid fabrics can be used in the weft.

These conveyor belts are mainly used in facilities with vertical transport (gradients of 90o) in diverse sectors, such as the chemical industry (fertilizer plants), port facilities, cement plants, grain elevators in silos and thermal power plants.

Sometimes an incorrectly installed splice or an oversized conveyor belt can damage the elevator to the point of complete failure. That is why at Kauman it is recommended not to settle for the durability or design of the belt supplied with elevator equipment years ago, since both the materials and the belt design have evolved.

Kauman provides a short training pill summarizing the key points to review and demand from your bucket elevator belt supplier:

At Kauman, development progresses alongside customers and distributors through real-life experiences, installations, and internal product improvement projects. For this reason, among other factors, the company has become a European leader in the manufacture of belts for bucket elevators.