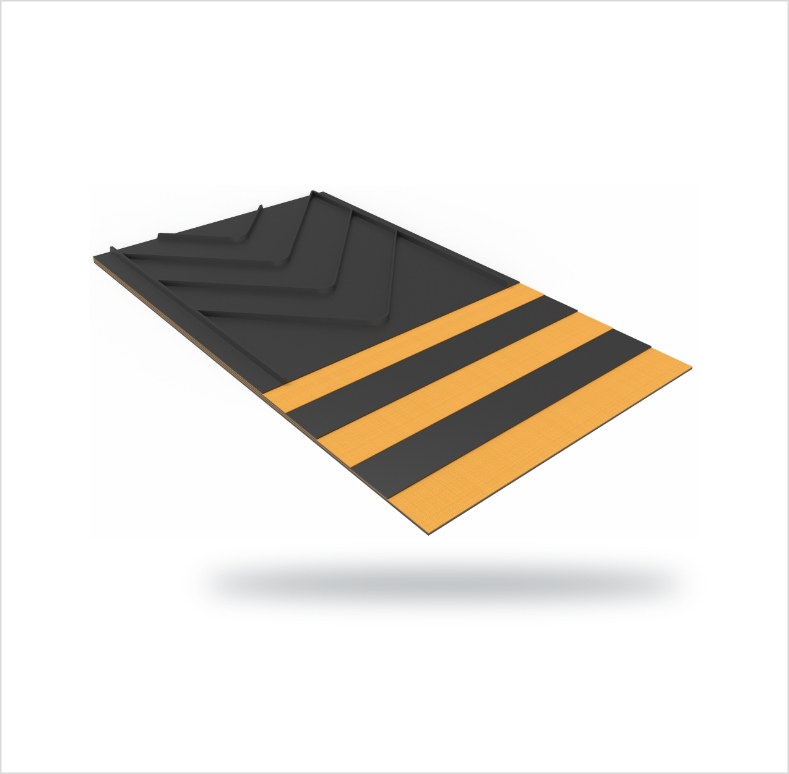

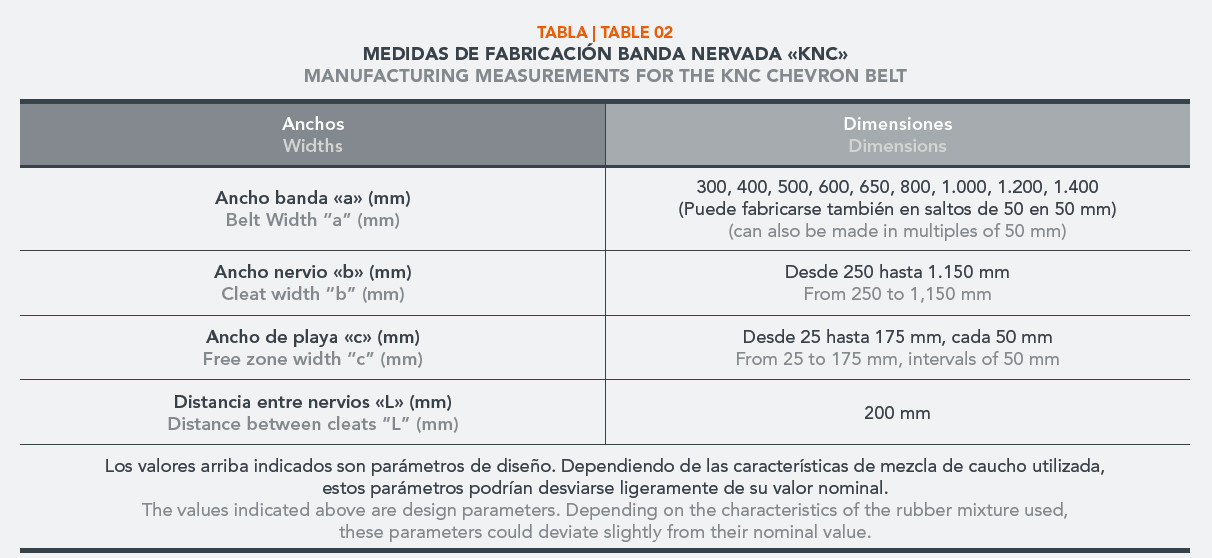

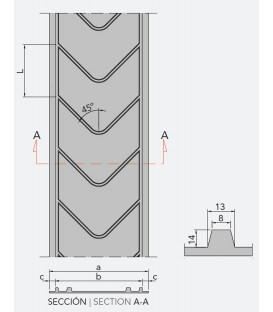

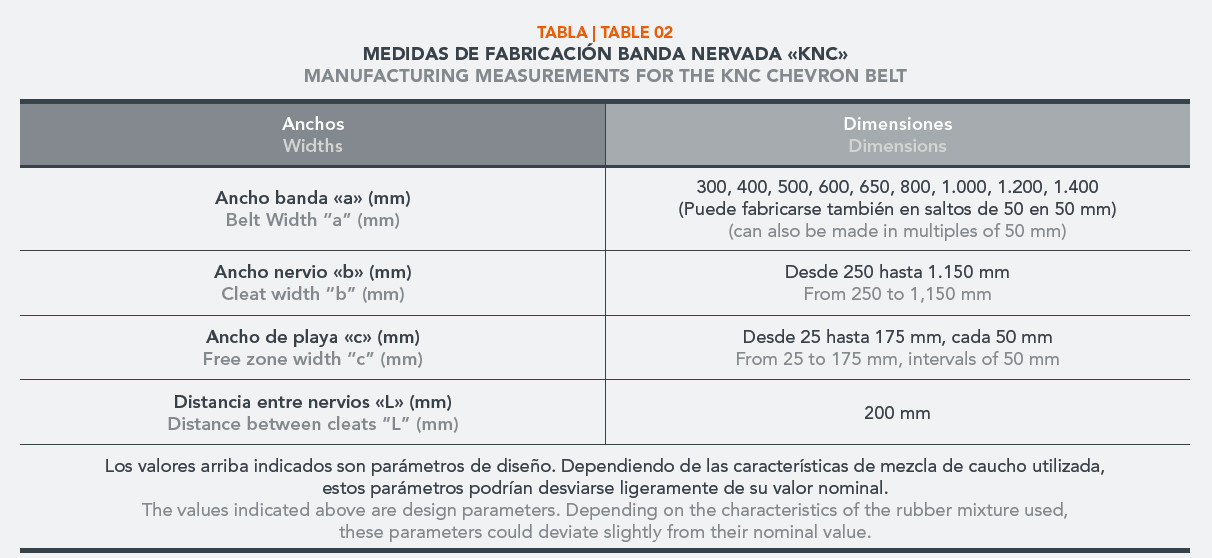

When a greater inclination is needed to carry solid material, anywhere between 20º and 45º, the outer cover should not be flat. Chevron belts are recommended for such cases, with edges and V-shaped cleats, as the holding capacity is greater.

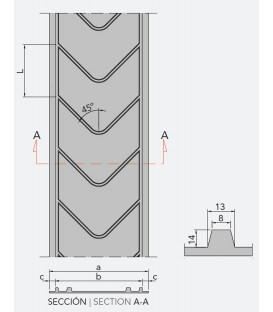

In facilities where the inclination changes, up to a maximum of roughly 45º, KNC conveyors are very suitable. The cleats leave a free zone at the edges of the belt, so that a side guide can be included on the working face to adapt the belt to varying inclinations.

These belts are normally made with rigid weft reinforcement, to stop the belt from becoming deformed when the inclination changes. This kind of belt is also used when side walls are installed to stop material from falling off.

Chevron belts with a textile carcass have numerous industrial uses, among which we could highlight the following sectors: mining, ports, primary equipment manufacturers, cement plants, thermal power plants, chemical, iron and steel, metallurgy, quarries and sand plants, the food industry, recycling and glass plants.